Chip Away Costs

Finding a better, cheaper way to make microchips that can be used as diagnostic tools.

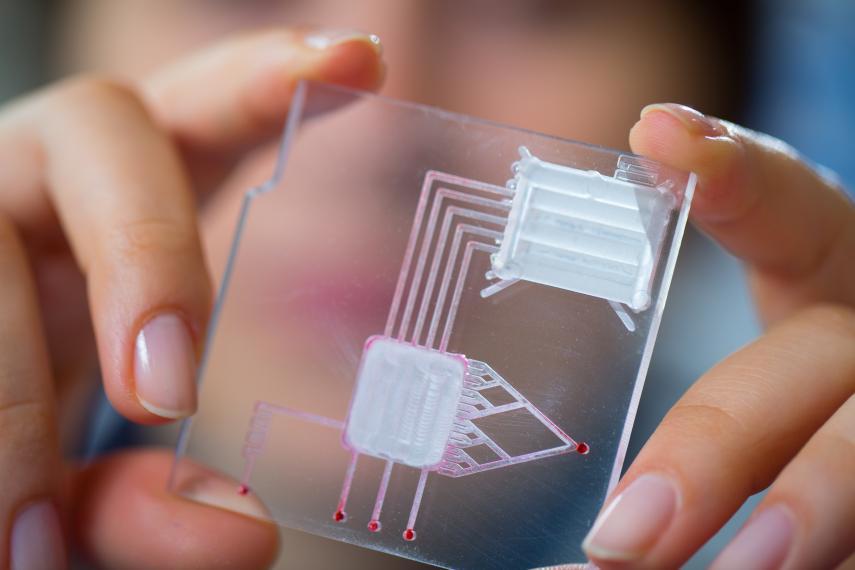

There are microsystems all around you. These miniature electronics that range from the size of a red blood cell to the head of a pin have revolutionized technology because they pack a lot of processing power despite their diminutive size. Microsystems can be found in many devices like cell phones, pacemakers, airbag sensors and more. Microfluidic chips, a type of microsystem, have tiny sensors that can interact with the environment; they can process tiny volumes of liquids, making them useful as a ‘lab-on-a-chip’ for healthcare diagnostics, food safety testing, and DNA analysis. For example, a doctor could use a lab-on-a-chip device to analyze a blood sample right after collecting it, so the patient could be diagnosed much sooner than if it were sent to a lab for testing. However, the use of lab-on-a-chip systems in healthcare and other industries has been limited thus far, in large part because of the complex, expensive technique that is currently used to build them.

University of Guelph engineering professor Christopher Collier and his research team found that an effective microsystem can be created in a simpler, lower-cost way by using the material graphene. Graphene is the thinnest, strongest and most conductive material on Earth, making it an ideal candidate for building microsystems. The research team made two lab-on-a-chip systems: one using the traditional method and one using a novel laser method to shape or ‘etch’ graphene to prepare it for lab-on-a-chip applications. The laser-etching technique was much simpler than the traditional technique, which involves a complex recipe, UV exposure, and chemical etching. They found that the graphene-based system had higher electrical activity and ‘wetting’ properties, which enables improved control over the movement of liquid droplets within the microsystem and thus improved performance. Overall, the lower cost graphene-based microsystems performed as well as traditional microsystems, if not better.

"Microfluidic chips can be made with laser-etching of graphene for reduced cost without reduced performance. This makes microfluidic technology more accessible and supports innovation in academic and industrial settings,” says Collier. “We hope to see widespread use of lab-on-a-chip devices in the healthcare industry, for fast diagnostics, and in the food industry, for contaminant detection in food products."

This work was supported by the Natural Sciences and Engineering Research Council of Canada.

Del Rosso M, Brodie CH, Ramalingam S, Cabral DM, Pensini E, Singh A, Collier CM. Characterisation of graphene electrodes for microsystems and microfluidic devices. Scientific Reports. 2019. doi: 10.1038/s41598-019-42108-x