From Sugar to Fuel: A Catalyst's Journey

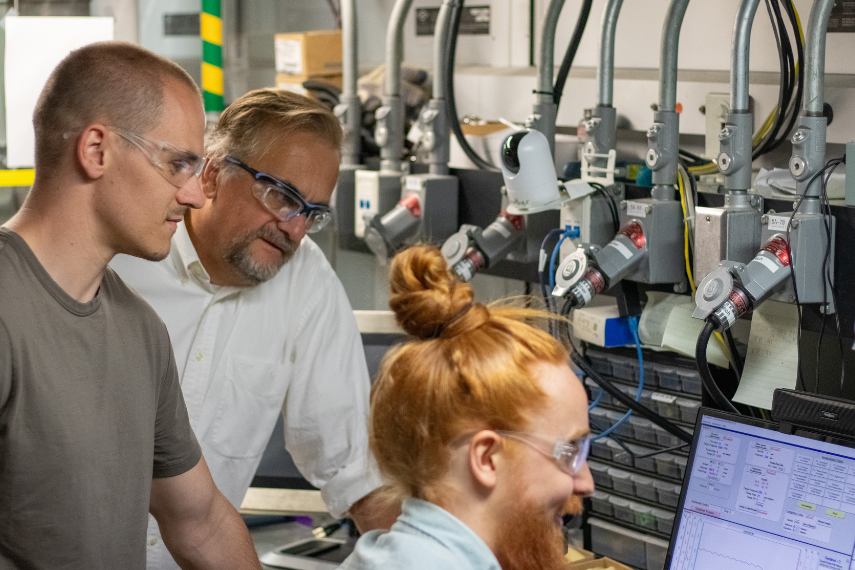

In the Summerlee Science Complex, researchers are turning to an unexpected source in their quest to reduce our reliance on crude oil and natural gas: sugars. PhD candidates Gabriel Hart and Aidan England are working with Dr. Marcel Schlaf to explore how these abundant molecules can serve as viable alternatives. Schlaf elaborates on their goals, "We are delving deep into the world of catalysts, attempting to transform abundant sugars like glucose into basic chemicals. These chemicals are primary components for not only polymers but also potential fuels, lubricants, resins, and even pharmaceuticals."

He further emphasized the importance of replacing carbon feeds from non-renewable sources, citing the environmental footprint of nylon manufacturing as a prime example.

A Two-Decade Pursuit

Having devoted 20 years to this project, Schlaf and his team are exploring the synthesis of molecules with a carbon chain, essential for the petrochemical supply chain. Their recent paper, published in ACS Catalysis, presents the conversion of a glucose derivative, sorbitol, into 1,6-Diacetoxyhexane – a compound that has potential as a precursor for nylon manufacturing. While still in the proof-of-concept phase, Schlaf is hopeful that his group’s findings will capture the interest of big petrochemical companies.

In chemical reactions, internal standards are usually applied to measure results without disrupting the process. However, in a recent study, the internal standard unexpectedly interacted with the catalyst, leading to a change in the outcome," Schlaf clarifies. "This was surprising because the standard is typically non-reactive and should not affect the reaction. The team is now investigating this anomaly further to gain a full understanding of what happened.

From Laboratory Benches to Industrial Giants

The implications of their work are profound. If successful, they could offer a robust and sustainable alternative to current petrochemical processes. "However," he cautions, "translating this from a batch process to a continuous flow process would require more research, funds, and collaboration with major petrochemical players." The challenges are real, especially when considering the scale. "You're talking about industrial implementations of 100,000 tons or more," he adds.

Beyond Research: Training Future Scientist

Beyond scientific achievements, Schlaf is immensely proud of the learning environment fostered in his lab. His students receive an interdisciplinary education, dabbling in organic, inorganic, and physical chemistry, chemical engineering, and even computer modeling. "The breadth of training my students receive is quite unique," he says.

Schlaf remains hopeful and explained that science often plays a long game. While commercialization may be years away, every step scientists take brings us closer to a more sustainable future.

This story was written by Mehran Bozorgi as part of the Science Communicators: Research @ CEPS initiative. Mehran is a PhD candidate in the School of Engineering under Dr.s Syeda Humaira Tasnim and Shohel Mahmud. His research focus is on the development of solar-assisted cooling systems to achieve thermal comfort conditions in buildings in different climate conditions.

Funding Acknowledgement: The funding for this research was provided by a grant (RGPIN-2018-03845) from the Natural Science and Engineering Research Council of Canada (NSERC) and in-kind support in the form of CPU time was provided by the Computing Centre at the University of Waterloo and Compute Canada.

Reference: G. H. Slater-Eddy et al., “Conversion of Isosorbide Diacetate to 1,6-Diacetoxyhexane by a Combined Hetero-/Homogeneous Tandem Catalyst System,” ACS Catal., pp. 11323–11338, Aug. 2023, doi: 10.1021/acscatal.3c02708.