A New Catalyst in Plastic Waste Management

The Plastic Accumulation Problem

Plastic production surged in the 1950s with the onset of industrial manufacturing. Since then, plastic has become involved in almost every aspect of our daily lives, increasing the annual plastic production rate. The issue with plastics arises because only 9 per cent of global plastic waste is recycled. This means the rest is incinerated or accumulates in landfills, negatively impacting the surrounding environment.

Approximately 65 per cent of municipal plastic waste is Polyethylene-based (PE) plastic due to its widespread applications. These range from plastic wrap and food packaging to the plastic pipes in our homes and our re-usable water bottles. While PE-based plastics sit in landfills as waste, they are trapping potential energy and hydrocarbons that are comparable to conventional fuels. Researchers in the University of Guelph’s School of Engineering have developed a new catalyst for pyrolysis, which is the thermochemical conversion of plastic waste into valuable hydrocarbon products, like fuel.

A Catalyst in Solving the Plastic Waste Crisis

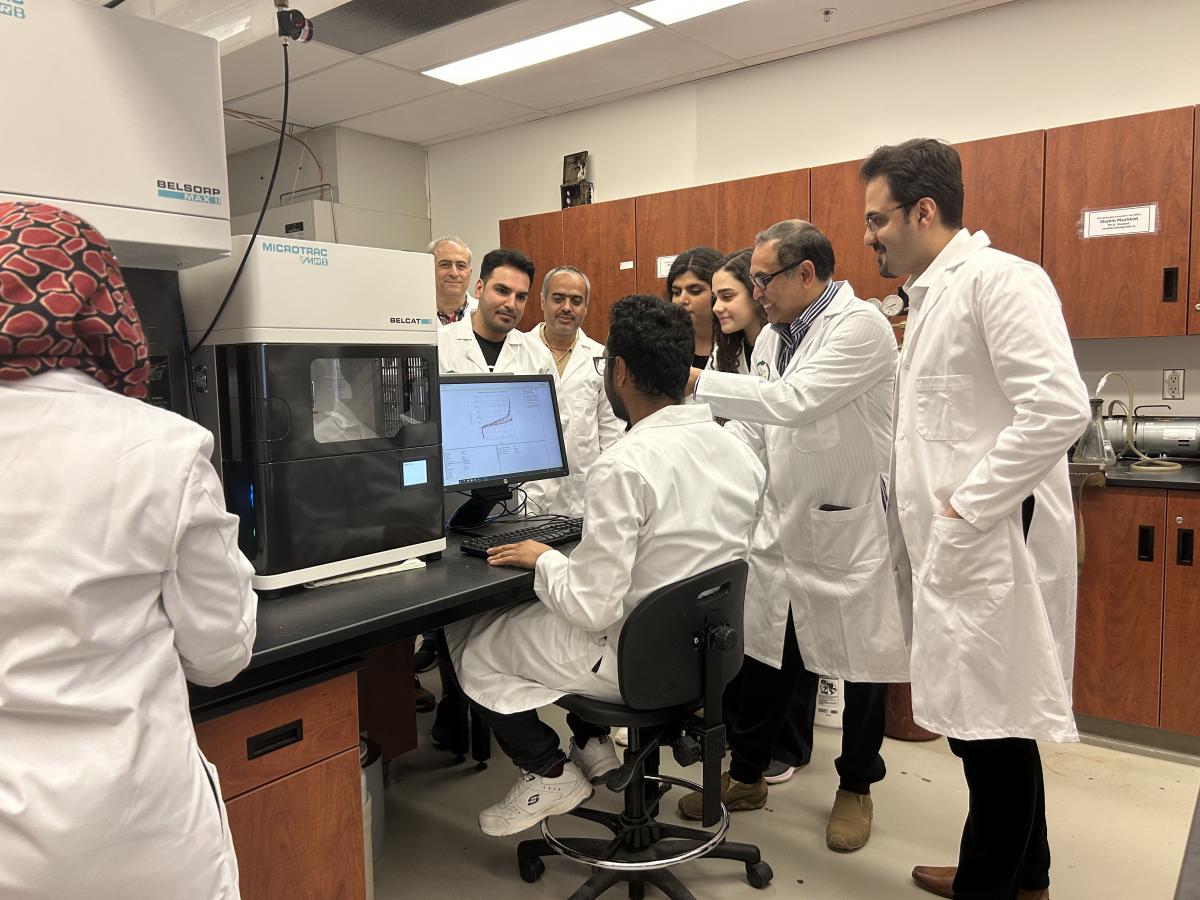

As Director of the Bio-Renewable Innovation Lab (BRIL) at the University of Guelph, Dr. Animesh Dutta researches ‘closed-loop solutions’ for plastic production and subsequently plastic waste management. This means Dutta and the researchers at BRIL attempt to recover value from every step of plastic waste conversion, allowing the outputs of one chemical process to be utilized as the inputs in the next, thus closing the loop.

Catalytic pyrolysis presents a promising ‘closed-loop solution’ for plastic production. Metal-organic frameworks (MOFs) are a type of catalyst for pyrolysis that are structurally similar to catalysts used in the petrochemical industry. However, MOFs lack the thermal stability needed at pyrolysis temperatures, so the researchers at BRIL developed a new Graphene-based MOF (GMOF) catalyst. Their cerium (III) nitrate hexahydrate MOF provides a high surface area for reactions, while the graphene oxide (GO) nanosheet it is grown on offers the stability and excellent thermal conductivity required for pyrolysis. Their GMOF catalyst improves the catalytic pyrolysis of PE-based plastic wastes by selectively producing the smaller hydrocarbon products which are used as starting materials in plastics production.

Plastic Waste Generates Valuable Hydrocarbons

Propylene is one of these small hydrocarbon products that Dutta’s novel catalyst produced from PE-based plastic waste. Propylene is the precursor to making Polypropylene (PP), which along with Polyethylene (PE) is one of the seven different types of plastic. This novel catalyst allows for PE plastic waste to be re-generated into new PP plastic products, showcasing its positive environmental impact.

“While our catalyst showed great potential in enhancing catalytic pyrolysis products of PE-based plastics, we are still researching the optimal catalyst design and process conditions to further improve the valuable hydrocarbon selectivity and yield,” said Dutta. Overall, this novel GMOF pyrolysis catalyst has laid the foundation for plastic recycling to become more sustainable, leading to less accumulation of plastics in landfills.

This work was supported by a Natural Sciences and Engineering Research Council of Canada Discovery Grant.

Norouzi O., Haddadi S.A., Salaudeen S., Soltanian S., Bartocci P., Arjmand M., Dutta A. Catalytic upgrading of polyethylene plastic waste using GMOF catalyst: Morphology, pyrolysis, and product analysis. Fuel. 2024 Aug 1. doi: 10.1016/j.fuel.2024.131742